Mechanical test on an analogue compatible with Nobel Biocare Branemark 4.1, using a M2 dynamic screw (recommended torque 25N·cm) and a 3.0 Dynamic® TiBase.

The test was carried out simulating real working conditions in a clinic, exerting an inclination of 30° ± 2° with the 3.0 Dynamic screwdriver DSPDCLH-24, in relation to the axis of the screw during its tightening and gradually increasing it until failure of one of the fastening components.

Objective: The objective is to evaluate the torsional resistance of the fastening components screw-screwdriver from the 3.0 Dynamic System.

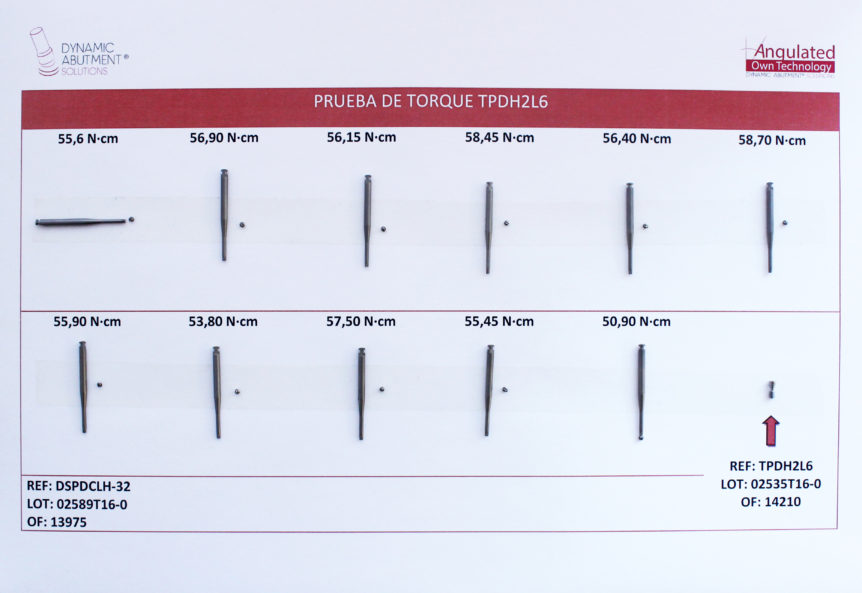

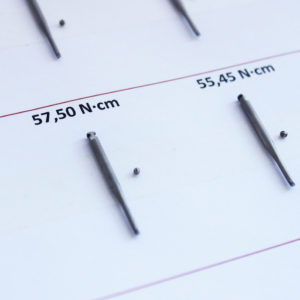

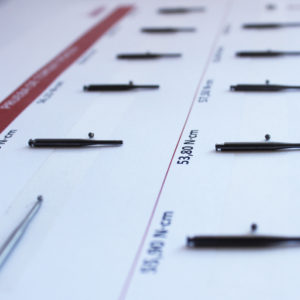

First, we tightened the set with the same screw, until the screwdriver failed at 55.6N·cm. We obtained 10 consecutive screwdriver failures, with an average torque of 56.4N·cm. Secondly, the screw resisted applicable force loads, until the 11th test. In the 11th test, the head of the screw stripped with a torque of 50.9N·cm, reaching maximum levels of torque and ensuring the safety of the screw, as the maximum torque recommended for this screw is 25N·cm.

To conclude this test, we can ensure the durability of the mechanical properties of the head of the 3.0 Dynamic screws. We can guarantee their integrity in the clinic, as the screwdriver acts as a security fuse on the head of the 3.0 Dynamic screw and ensuring the patient safety.

Test table with torque, screw and angulation parameters

Test table with torque, screw and angulation parameters

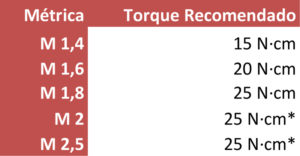

Table of metrics with recommended torque. * Up to 30N·cm

Table of metrics with recommended torque. * Up to 30N·cm

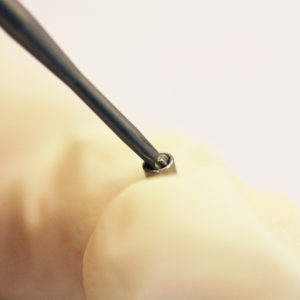

Detail of Screwdriver Assembly of the Dynamic System 3.0

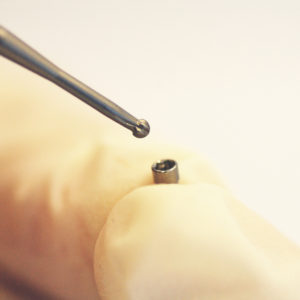

Detail of the mechanical test to torsion on a set 3.0 Dynamic® TiBase+ Analog

Dynamic metric screw 2, before and after the test