An evaluation from the flexural-torsional resistance of the Screwdriver set of 3.0 Dynamic Abutment® System has been carried out simulating real working conditions.

Stages during the flexural-torsional test, supported by the 3.0 Dynamic Abutment® Screwdriver:

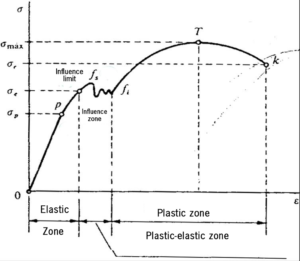

- PROPORTIONAL LIMIT STRESS: Highest stress at which stress is directly proportional to strain. It is the highest stress at which the curve in a stress-strain diagram is a straight line. (35 to 40 N·cm)

- YIELD STRESS: The yield stress, also known as elasticity limit, is the maximum stress that an elastic-plastic material can withstand without undergoing permanent deformations. (40 to 45 N·cm)

- YIELD STRENGTH: The yield strength is the point at which a material begins to deform plastically. It is where some fraction of the deformation will be permanent and non-reversible. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed. (45 to 50 N·cm)

- PROOF STRESS: Limit reached before a breakage of the element occurs. (50 to 60 N·cm)

- BREAKING POINT: The degree of tension or stress at which something breaks.

- (Máximum break value)

Conclusion:

Conclusion:

After performing the flexural-torsional test we can verify the strength of the set screw-screwdriver from 3.0 Dynamic Abutment® Solutions. There exists a very high safety range and in case of applying a high torque between 50 and 60N·cm by mistake, it will be the screwdriver that will break, keeping the screw head intact.

In Dynamic Abutment® Solutions we recommend a maximum torque of 25 N·cm (depending on the metric) for our 3.0 Dynamic screws, for this reason the values are kept below the proof stress during the application of the torque, which is more than sufficient provided that the prosthesis is passively seated on the implants.

In this way, we can verify the quality of our products, proving that the screwdriver is deformed and broken, not the screw, avoiding the slightest risk for our customers.